RFID & NFC tags

Bring your products

to life.

Used in security , but also for marketing campaigns,

smart labels.

RFID & NFC tags

Bring your products

to life.

Used in security , but also for marketing campaigns,

smart labels.

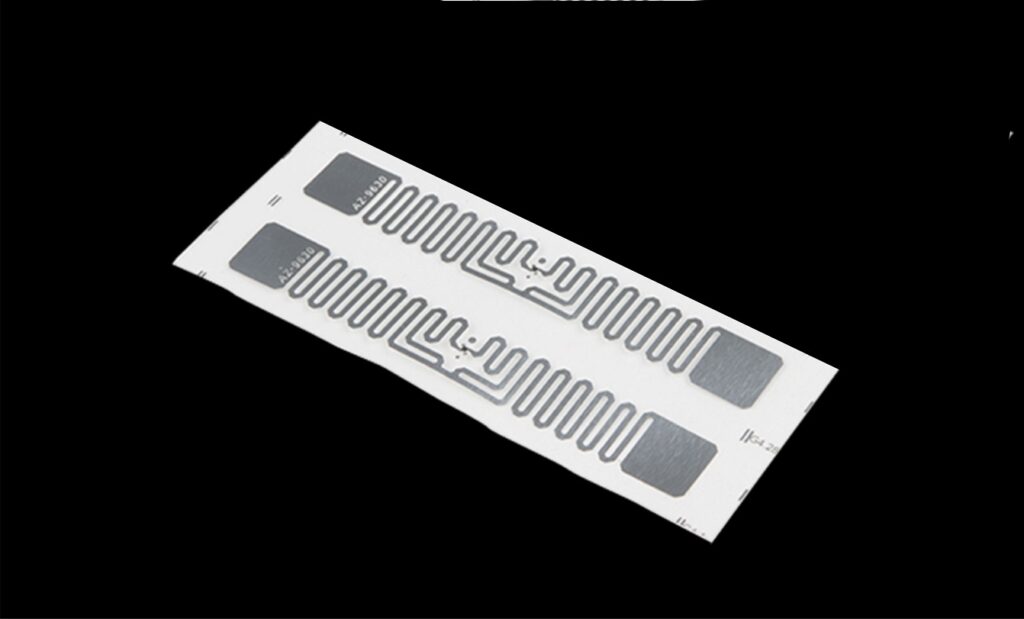

RFID

Auto-ID labels like barcodes and RFID are both used to track and capture information about products, assets and inventory. Both are used in applications such as tracking goods through the supply chain and managing inventory in industrial settings.

RFID is a mature technoloogy, as they are basically a microchip with an antenna, RFID tags are capable of storing huge amounts of data regarding a product:

Date of manufacture

Date of shipping

Serial Number, price , size, colour.

With the right kind of scanner this data can also be eddited, for example you could set up a system where the purchase date is added to the chip when scanned at point of sale. RFID is the future of POS and industry , improving stock control and supply chain logistics which has become a large commercial issue

RFID is a mature technoloogy, as they are basically a microchip with an antenna, RFID tags are capable of storing huge amounts of data regarding a product:

Date of manufacture

Date of shipping

Serial Number, price , size, colour.

With the right kind of scanner this data can also be eddited, for example you could set up a system where the purchase date is added to the chip when scanned at point of sale. RFID is the future of POS and industry , improving stock control and supply chain logistics which has become a large commercial issue

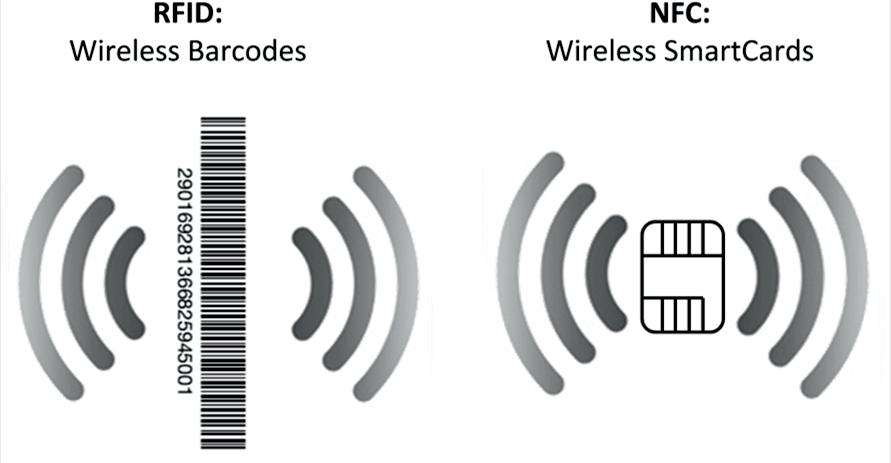

NFC tags

NFC is part RFID (radio-frequency identification) and part Bluetooth. Unlike RFID, NFC tags work in close proximity, giving users more precision. NFC also doesn’t require manual device discovery and synchronization as Bluetooth Low Energy does. The biggest difference between RFID and NFC is the communication method.

RFID tags have only a one-way communication method, meaning an RFID-enabled item sends a signal to an RFID reader.

NFC devices have a one- and two-way communication capability, which gives the NFC technology an upper hand in use cases where transactions are dependent on data from two devices (e.g., card payments). Mobile wallets like Apple Pay, Samsung Pay, Android Pay, and other contactless payment solutions are all powered by the NFC technology.

So in essence, RFID tags are great for inventory tracking and NFC tags work well for enhanced communication.

RFID tags have only a one-way communication method, meaning an RFID-enabled item sends a signal to an RFID reader.

NFC devices have a one- and two-way communication capability, which gives the NFC technology an upper hand in use cases where transactions are dependent on data from two devices (e.g., card payments). Mobile wallets like Apple Pay, Samsung Pay, Android Pay, and other contactless payment solutions are all powered by the NFC technology.

So in essence, RFID tags are great for inventory tracking and NFC tags work well for enhanced communication.

NFC has many industry uses including:

- Identification

- Physical Access

- Ticketing

- Loyalty & Membership